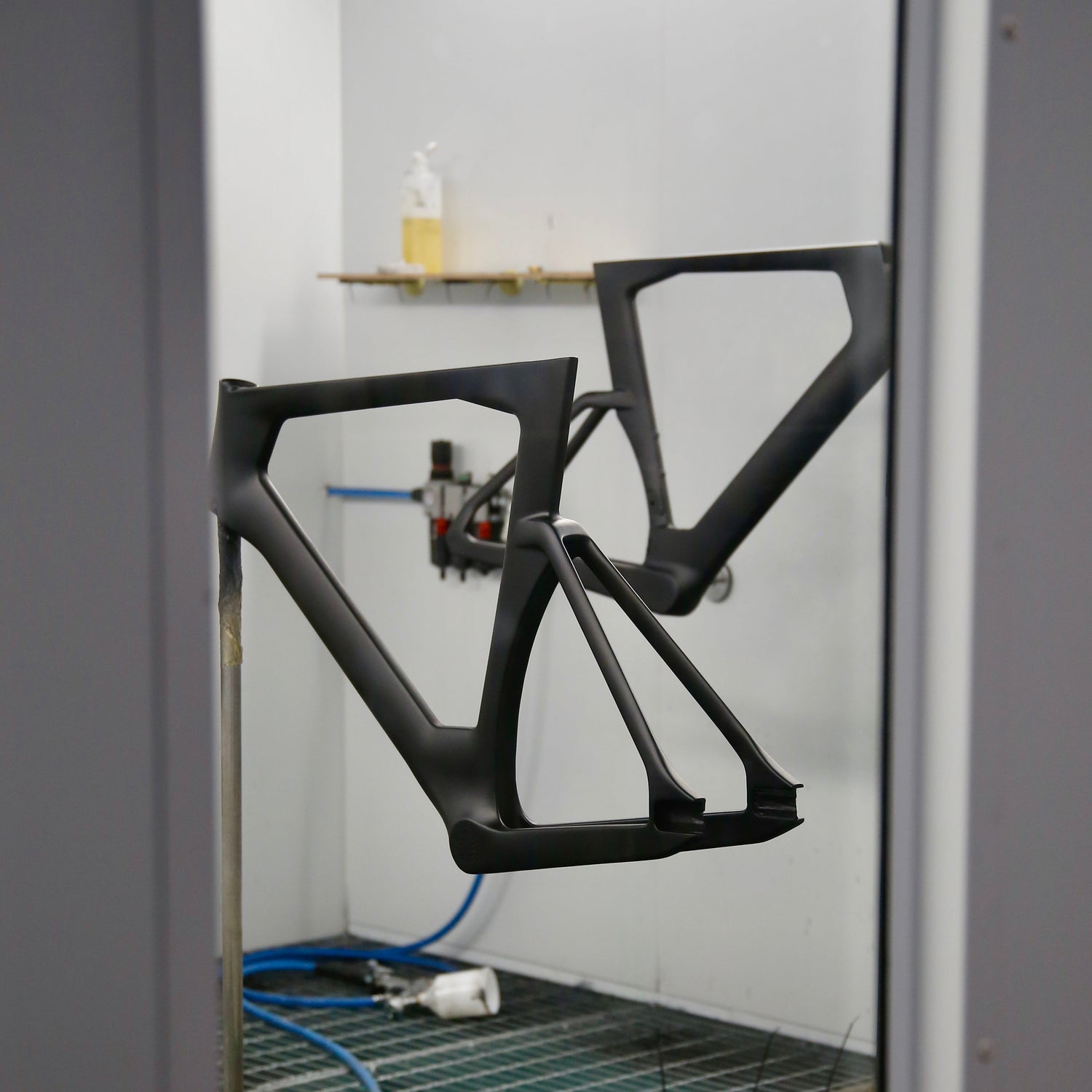

Introducing the latest addition to the Handsling workshop - of a state-of-the-art downdraft spray paint booth.

This professional facility allows us to bring frame painting and finishing in house. Carbon frames are now imported in a raw state from our Shenzhen factory and fully finished in the UK, before being built into complete bikes.

Our customers now have access to an even wider range of colour choices, as well as almost limitless customisation options. There aren't many other bike brands (if any) that can match our 30 frame colours. And with frames painted to order on site, lead times will be reduced.

Handsling founder Simon Whiten said: “Every bike that leaves the workshop is custom built to a rider’s size and specifications, meaning no two bikes are the same. Being able to offer such a wide range of paint finishes and colours adds to the exclusivity of each bike.

“Bringing paint to the UK enables us to exercise even greater control over the end-to-end frame production process, resulting in better quality, more choice, and faster production of bikes.”

He added: “We want to thank our customers for their patience and understanding as we go through this major operational shift. As we get fully up to speed, we can ensure that the exact model, size and colour that a customer wants is always available.”

The booth itself was supplied by Staffordshire company Haltec. The Airstream 1 Max Air spray booth oven is an enclosed unit with double skin insulated panels. Key features include gridded raised floor extraction and air recirculation on the bake cycle for fuel economy.

The intake and extract system is made up of two direct drive fans. LED lighting is provided by high efficiency PCB boards. An adjoining paint mixing room is also double insulated with extraction at bench and floor level.

Installing the booth required an overhaul of the workshop’s three-phase electricity supply, as well as specialist gas installation to the burner. A separate standalone oven provides extra capacity for curing frames.

With the booth taking up a significant area of floorspace, Handsling is installing a new mezzanine level to provide sufficient space for bike building. We've also recruited qualified paint specialists and expanded our team of bike builders in anticipation of higher demand.

The paint team is being run by Kat Varga (below), a painter with decades of experience in spraying bicycles and motorcycles. The plan is that, with her background in custom designs on Harley Davidson motorcycles, customers will be able to request a wide array of personalised finishes and additions under our soon to launch custom painting program.

Stay tuned for updates as painted frames emerge from the booth, including our new models - the TSTRevo time trial / triathlon bike, the TR2evoP track pursuit bike, the TR2evoS track sprint bike, and the A1R0evoS lightweight road bike.

Customise Your Handsling Bike

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.